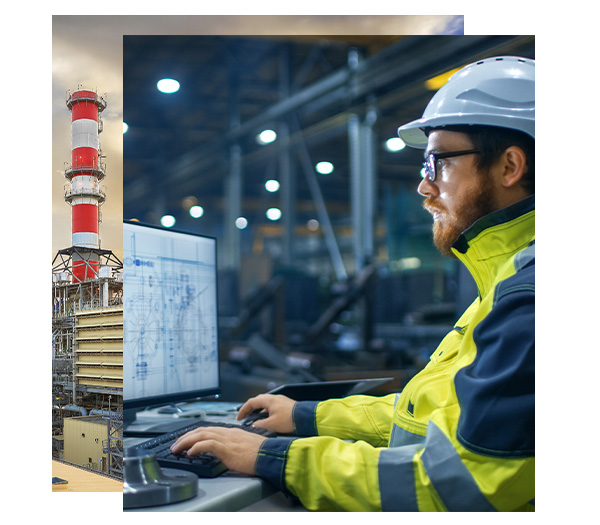

Combined Cycle Performance Test

TGPS has conducted performance testing of combined cycle power plants around the world.

TGPS has conducted combined cycle performance tests of plants under different configurations (1 x 1, 2 x 1, 3 x 1, 4 x 1).

We are also experts of testing a combined cycle in multiple phases; first the gas turbines are fully commissioned and tested in simple cycle configuration and the second when the whole combined cycle is in operation. We are used to develop complex combined cycle performance test procedures and calculation tools to handle this scenarios.

Our company owns stock the necessary high-precision testing instrumentation to measure the main parameters around the combined cycle.

The typical parameters of interest to calculate for contractual purposes are:

Understanding your operations costs such as start-up and shutdown costs, frequency regulation, spinning reserve and other ancillary services is key to your bottom line. TGPS has helped to determine these values in power plants around the world. It is useful to understand these costs for hot, warm and cold conditions.

With this information, our customers can make smart decisions for investment and maintenance purposes.

The typical test that TGPS conducts in Combined Cycles are:

In addition to the above tests, TGPS can conduct the emissions test and acoustic test on combined cycle power plants.

Performance Testing Projects

Get In Touch

Learn more about how Thermogen Power Services can provide solutions and flawless execution to meet your specific requirements.