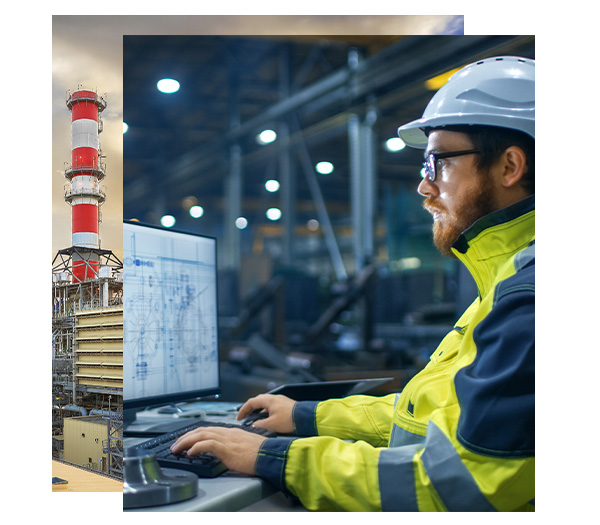

Gas Turbine Performance Test

TGPS has conducted the thermal performance evaluation of gas turbines around the world.

The typical parameters of interest to calculate for contractual purposes are:

Recently, several customers have been interested to understand better the start-up and shutdown costs of their units. TGPS has helped to determine these values in power plants around the world.

Using all this information, our customers can take smart decisions for investment and maintenance purposes.

The typical test that TGPS conducts in Gas Turbines are:

Performance Testing Projects

Get In Touch

Learn more about how Thermogen Power Services can provide solutions and flawless execution to meet your specific requirements.